Vacuum Chamber Molding

Compression molding or laminating on a press equipped with a vacuum chamber pays off in faster production, higher quality and reduced scrap parts. Surrounding the workpiece with a vacuum removes heated gases, trapped air and harmful vapors from the part, thereby eliminating defects.

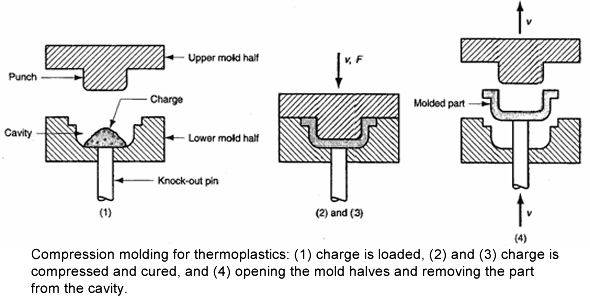

Compression Molding Process

Compression molding is a process in which a preheated polymer is placed into an open, heated mold cavity. The mold is closed with a top plug and pressure is applied to force the material to contact all areas of the mold. Throughout the process heat and pressure are maintained until the polymer has cured.

While the compression molding process can be employed with both thermosets or thermoplastics, today most applications use thermoset polymers. Advanced composite thermoplastics can also be compression molded with unidirectional tapes, woven fabrics, randomly orientated fiber mat or chopped strand.

Compression molding is a high-volume, high-pressure plastic molding method that is suitable for molding complex, high-strength objects. And with its short cycle time and high production rate, many organizations have chosen compression molding to produce parts